The spending on the packed foods in India is still low when compared with other countries of the world. But this trend in increasing as there is demand for packed foods due to rapid urbanization, increase in disposable income and growth in young working population. The annual growth is in region of 13 – 15 % which is expected to take the packing industry of India to 32 billion dollars in the next four to five years.

Private and public sectors are working together to create at least 30 food parks. These parks will encourage the growth of packing industry, related infrastructure, packing transport and refrigeration facilities. The boost from establishing food parks will see an investment of around 25 billion $ in next few years in the food packing industry.

The increase in middle class population of India and its rising disposable income will push the growth of packing industry into north ward direction. The total value of world packing industry is around 550 billion $. The share of India in the world packing industry is of around 16 billion $, which is bound to increase with the changing lifestyle in India in coming years.

Within India also packing industry is not just confided to packing food and related items, it also packs drugs, medicines, fruits juices, spices, electronic items. The packing industry spans many other industries also. The growth of e commerce industry will further give big boost to the packing industry, as the quality packing will be one of the marketing strengths of the e commerce companies.

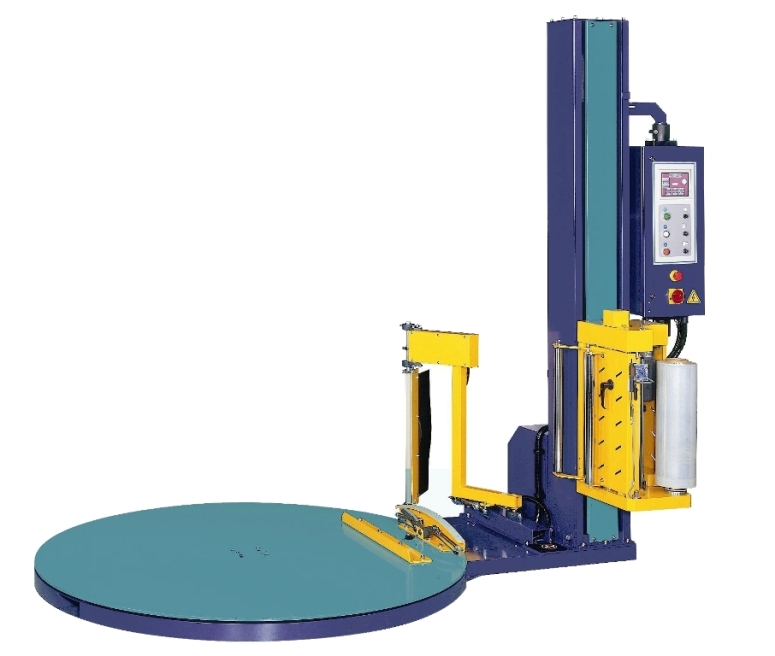

Today, the packing industry Robopac India in India is highly segmented and most of the industry is dominated by small and medium companies. The suppliers of machines, raw materials and related services are all fragmented into small companies. In future , the growth will encourage some big companies to merger small companies and create space for more production in packing materials , and increase scale by using latest technology with reduce manpower in various stages of the processing and packing .

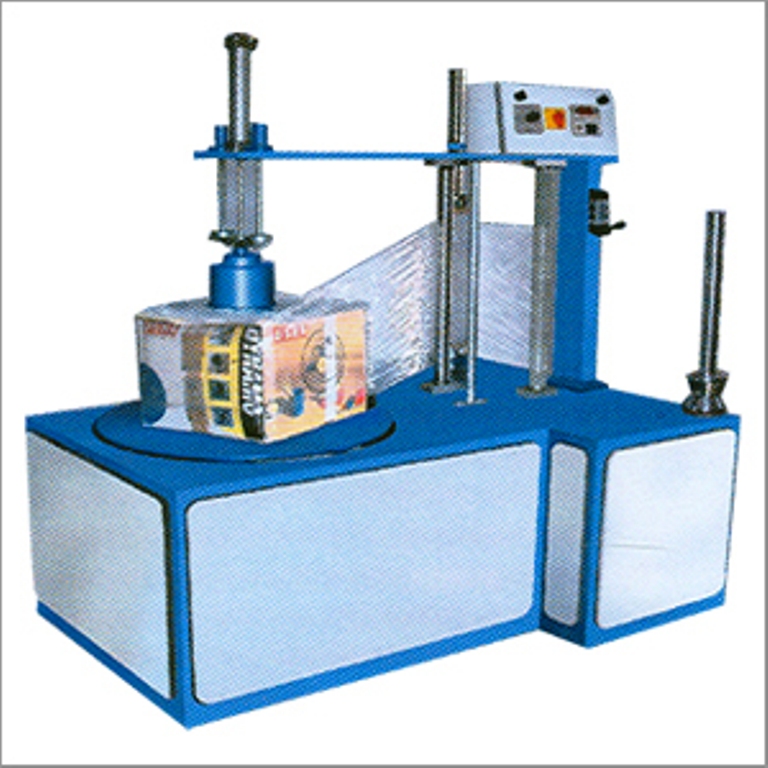

The marketing agencies have highlighted the problems faced by the small and medium companies. Almost all of them suffer from high cost of raw material, lack of adequate credit for expansion, lack of regular power supply, unskilled manpower and lack of proper training to market the brand and streamline the distribution system. But the preferences and expectations of the customers are Carton Wrapping Machine increasing, which is making packing more attractive, stylish, and easy to open and use of finest raw material to preserve the freshness of the material or foods items inside.